Formaldehyde

From greenfield-, revamping- and optimization-projects knowledge about following technologies are in the company:

9 different Metal Oxide Processes:

Perstorp Formox, Alder, DB – Western,

CAL Polymeres, Frati, Mapco, Reichold, Hiag

Chemoprojekt

12 Silver Processes:

Dynea, Krems Chemie, Karl Fischer,

Mitsubishi Gas Technology, Meissner, ICI,

Bayer, Dyno, Lambiotte, Wuxi Huali,

Wuxi Huayan, Russian silver tuff technolgy

Resin Plants:

Expansions and Greenfield installations up to 70 t batch size.

Modernisations of urea and melamine bulk handling systems for capacity increase, quality improvement and cost reduction

Energy optimisation in resin plants – focus electricity cost reductions

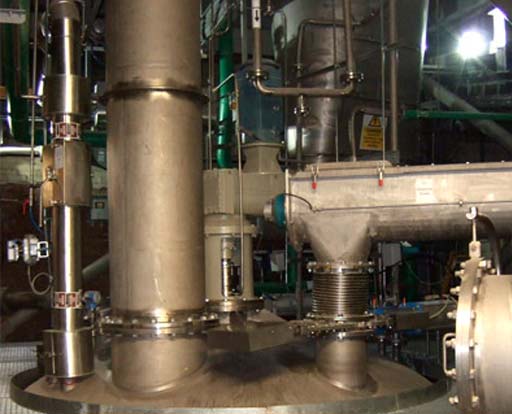

Turbo Charged Formaldehyde Process

Steam driven Chillers

Steam Turbine for power generation by pressure reduction and excess steam utilisation. Src: Siemens Frankenthal (ehemals KK&K)

Resin plant Upgrades – professional bulk handling